SK chemicals Site Manager● SK Chemical will become the top 4 cell culture

vaccine supply company!

SK Chemical (CEO and Vice-chairman Kim Chang Geun) is leading the development of [influenza cell culture vaccine using animal cell] in Korea.

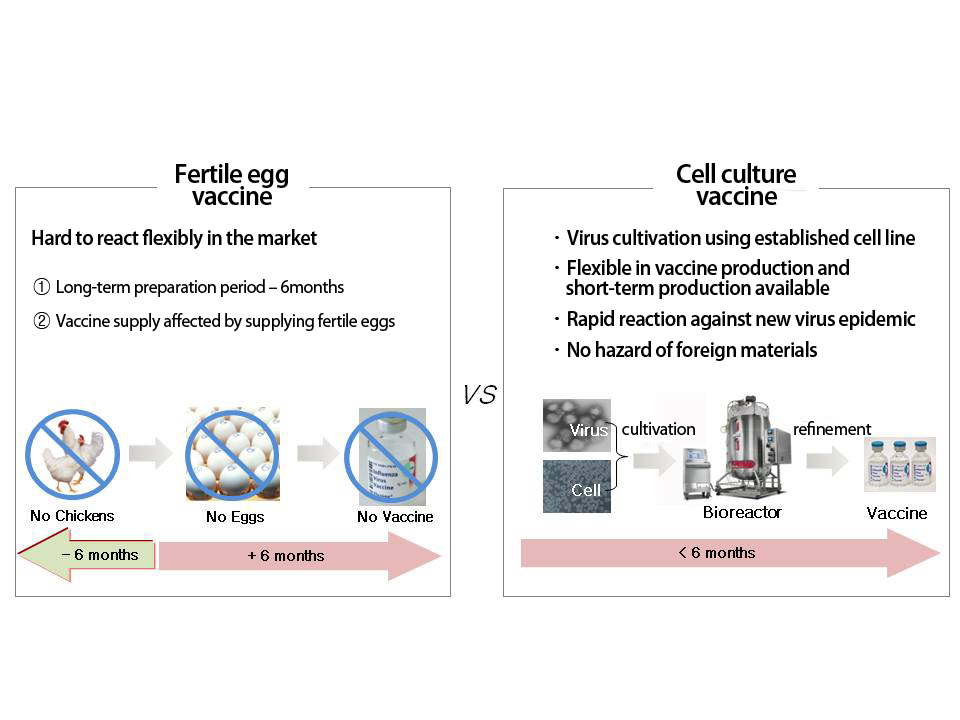

The cell culture vaccine SK Chemical is developing enables to react more flexibly the sudden increase of vaccine like swine flu compared with the current fertile egg vaccine which attracts worldwide interests as the state-of-the-art technology.

The fertile egg merits for its low cost and well established process, but has defects that it cannot produce a large amount of vaccine in a short period of time, and is vulnerable to external pollution such as mixing with swine flu or allergy inducing materials.

The fertile based influenza vaccine production technology was mainstream for a few years ago, but the companies like Novartis or Baxter have concentrated on the development of cell culture based vaccination.

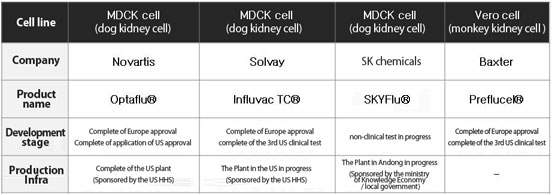

SK Chemical secured original technology for cell culture vaccination, completed the purification process of *[suspension culture process] to increase production yield, and also completed international patent application with the development of **[MDCK-SKY, own cell line of suspension culture application] the core of new productivity.

[MDCK-SKY], developed by SK Chemical, is available of mass production with low cost, and is assessed for its economical excellence compared with animal cell line.

The toxicity test is currently performed at MPI, a non-clinical test commissioned institution, for the overseas market, and it is expected that the 1st clinical test will be carried out the first half of the next year.

The company was appointed as a participation company for [Customized vaccine raw material production such as Influenza supporting project] sponsored by the Ministry of Knowledge Economy, Gyeongsangbuk-do and Andong-si and began construction a eco-friendly vaccine production plant in Andong in June 15, the largest cell culture vaccine production facility in Korea using ***[Single Use System].

[Single Use System] reduces cross pollution by using disposal equipment in system and product, and minimizes cleansing and sterilization process that achieves great quality improvement.

The animal cell using vaccines are verified for the safety and effectiveness by Novartis, Solvay and Baxter in the EU in the same volume of the fertile egg, and many more global vaccine companies are in the process of developing cell culture vaccine technology.

The SK Chemical Andong Vaccine Plant concentrates on the development of national compulsory preventive vaccines to localize imported vaccine by using influenza cell culture vaccine research and production technology, and also on the premium vaccine production such as infant pneumonia vaccine to grow a core of domestic vaccine production.

A strategic cooperation with multinational vaccine companies is considerable progressed for global markets. Thus, enhancement and commercialization of our vaccine technology seems to be achieved earlier than expected.

The development of animal cell using cell culture influenza vaccine not only consolidates national public health condition, but also plays an important starting point for vaccine R&D competitiveness and vaccine infra structure.

SK Chemical plans to be a global major through advancement to the leading market and WHO supply with the development of own technology in cell culture vaccine .

? - Appendix : Terminology

? - Terminology

* Suspension culture

When animal cell used to produce vaccine antibody is cultured in suspending condition it is available for mass production and cost effective for the process is simplified.

** MDCK-SKY

This is SK Chemical developing cell line for influenza culture. It is available for mass production and cost effective for the process is simplified as the animal cell is cultured in suspending condition.

*** Single Use System

Single Use System replaced the reactor by using disposable plastic pack. By the use of disposal packs, it reduces the production line construction cost by half and the construction duration by 1/3. There is almost no pollution as it is a disposable pack.