● SK chemicals, Successful Commercialization of Super-Engineering Plastic PCT

- World`s Second Successful Commercialization of PCT... First Application in Domestic Automotive Industry

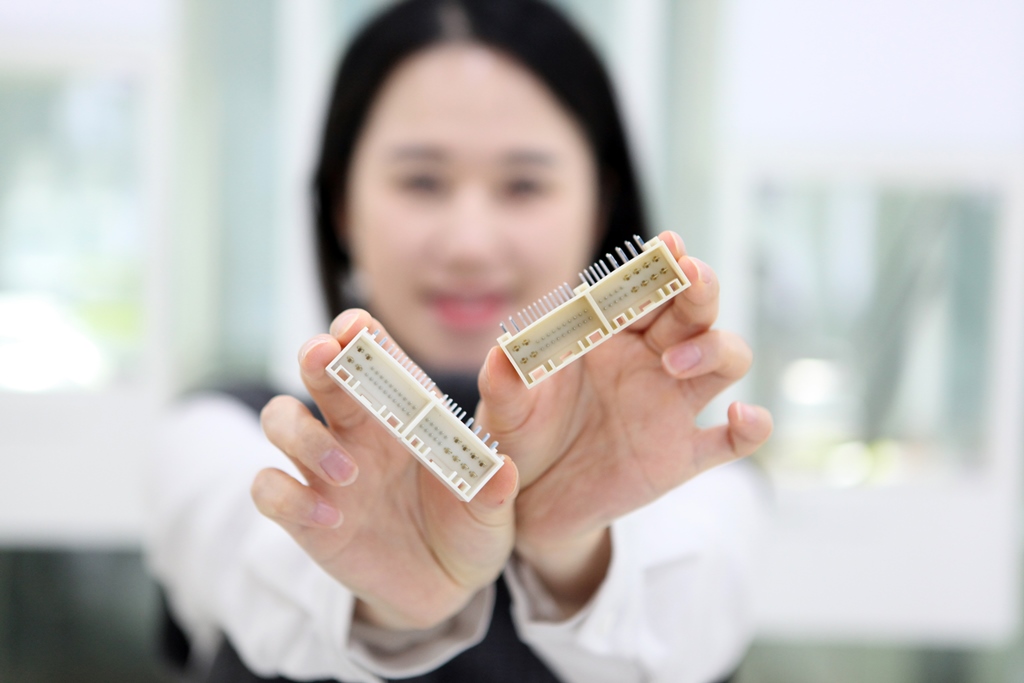

SK chemicals has succeeded in commercializing the super-engineering plastic polycyclohexylenedimethylene terephthalate (PCT) for use as an automotive material.

SK chemicals (Cheol Kim, CEO) announced on January 31 that their proprietary PCT super-engineering plastic had been registered as a standard material for domestic automotive parts manufacturers for application in electrical connectors for production vehicles to be released this year.

This is the first time that SK chemicals` SkyPura, the world`s second PCT material to be successfully commercialized in 2012, has been applied to automotive connectors. Traditionally, plastic materials such as PBT and PA have been mainly used for automotive connectors that connect electrical/electronic components and wires. PCT has been selected to replace such materials automotive connectors for its superior heat resistance and electrical characteristics.

Generally, when manufacturing a connector, surface-mounting technologies (SMT) are utilized to directly bond pins to plastic circuit boards via plastic welding. [merged] Temperatures generated in this process exceed 230°C.

However, since eco-friendly manufacturing methods have been introduced to phase out the use of lead (Pb), a heavy metal, SMTs have also changed to be lead-free. Because maximum temperatures rise in excess of 260°C in lead-free SMT processes, the demand for super-engineering plastics with greater heat resistance has increased. Due to its high melting point of over 285°C, SK chemicals` SkyPura is suitable for stable, deformation-free manufacturing, even for connectors with a high number of pins.

Notably, PCT has received the highest grade of "zero" in the comparative tracking index (CTI) test that measures the electrical breakdown properties of insulating materials. The CTI test introduces artificial contamination between electrodes to test whether electricity is conducted through the pollutants. When circuit boards or connectors are manufactured with PCT, high insulation is maintained even if pins or electrodes are contaminated, thus reducing the probability of malfunction at high voltages and making PCT suitable for electric/electronic components.

SK chemicals` Head of EP Division Tae-geun Han stated, "Recently, the use of electronic equipment has increased in not only electric vehicles but in general vehicles as well. We plan to replace more than 5% of the plastics in the automotive connector market - which is estimated to be about 60,000 to 70,000 tons annually worldwide - with SkyPura in the next three years."

SK chemicals developed the super-engineering plastic PCT by chemically bonding terephthalic acid (TPA) and cyclohexanedimethanol (CHDM), and the successful commercialization of the material has been recognized as one of ten major emerging technologies, with SK chemicals being awarded Gold-Minister Award by the Ministry of Trade, Industry, and Energy (MOTIE) in 2013.

Unlike typical engineering plastics that improve poor heat-resistant properties inherent in plastic, super-engineering plastics offer incredibly high heat and chemical resistance and can be applied in various industries, even replacing metals in certain applications. [merged]

[Photo]

In addition to automotive connector applications, PCT is currently used in LED reflectors, the core material in LED-backlit displays.

[Glossary]

* Connector

Devices that maintain electrical connections in electrical/electronic applications.

* Polybutylene terephthalate (PBT)

A type of polyester produced via polymerization of DMT or TPA and 1,4-butandiol. Widely used as a compounding product with glass fiber reinforcement due to its rapid crystallization, superior moldability, and other physical properties.

* Comparative tracking index (CTI)

Method of testing conducted by UL under the UL746A standard. Measures the electrical breakdown (tracking) properties of an insulating material. Performance level categories (PLC) range from 0 and 5, with 0 being the highest level of insulation. The distances between electrical circuits have become shorter as circuit boards are made to be smaller and thinner. As a result, breakdown of circuits occur readily when contaminated. Safer and more durable products can be produced by using stable plastic materials on circuit boards.

* Surface-mount technology (SMT)

A type of packaging technology that directly bonds and integrates many electronic components onto limited printed circuit boards (PCB). Machines automatically place and solder components that are difficult to handle manually.

* LED reflector

Located on the rear side of an LED emitter, the reflector reflects the emitted light to improve efficiency with respect to the light-emitting direction.