● SK chemicals’ SKYPLETE launches on the global market with customized materials

- Showcases industrial and educational outputs in the world`s biggest 3D printing exposition

- "SKYPLETE will top the 3D printing materials market that`s growing 20 percent annually."

The innovative 3D printing material developed by SK chemicals is going global.

SK chemicals (CEO Kim Cheol) reported taking part in the world`s largest 3D printing conference "2017 RAPID TCT" May 9th ~ 11th in Pittsburgh and showed off its high-functionality 3D printing material "SKYPLETE."

At the conference, SK chemicals demonstrated a variety of 3D printing outputs like △ airplane propellers, △ car seat lumbar supports and other automotive parts, industrial products like hard drive △ SD card storage boxes, △ office supplies, and consumer goods like △ tubes and shoe soles.

Materials used in most 3D printers have problems with high temperature outputs that warp during cooling or when exposed to processing chemicals like acetone because of weak chemical resistance. The release of volatile organic compounds (VOC), including environmentally harmful substances like bisphenol A, have also been reported.

SKYPLETE is a revolutionary material that overcomes the limitations of existing products while meeting customers’ needs. Available in T, L, G, and E series product groups, SKYPLETE allows 3D printer production of products requiring different physical properties.

The functionality of the T series is proven by shock resistant products that also withstand temperatures over 100°C. It is considered an ideal substitute for polycarbonate since there are no environmentally harmful substances produced in the process. The T series’ chemical resistance allows chemical processing needed for electric and electronic product applications.

The L series boasts excellent elasticity, which overcomes the limitations of bending during filament feeding and subsequent extruding problems so waste and production costs are reduced. With its superior mechanical properties over currently available thermoplastic polyurethane elastomers, major sports and functional shoe brands are keenly interested.

The environment-friendly G series has passed U.S. Food and Drug Administration tests for marketing as drug packaging. The E series displays superior heat resistance (>100°C) over existing polylactic acid, plus twice the printing speed!

Oh Joon-seok, senior manager for business development at SK chemicals, said, "The world`s leading 3D printing companies like Stratasys were keenly interested in our SKYPLETE at the trade show." He added, "We are expanding to the global market with SKYPLETE to satisfy the wide range of highly specialized customer needs."

According to the 3D printing industry publication Wholers Report 2016, the 3D printing materials market is currently estimated at $800 million, with an annual average growth rate of 20 percent. SK chemicals will focus its marketing efforts on North America, which accounts for 40 percent of the global printing market.

RAPID TCT, 25 years since its launch, is one of the biggest 3D printing conferences in the world and recognized as one of the world`s top-five 3D printing expositions along with Inside 3D Printing (U.S.), formnext (Germany), TCT Asia (China), and Additive Manufacturing Shows (Britain). This year, as many as 335 firms took part in the show, up 45 percent from the previous year, showing that companies the world over are interested in the fast-growing 3D printing sector.

SK chemicals participated in the K Show last year in Germany and Inside 3D Printing Conference & Expo 2017 in March to showcase SKYPLETE as the material poised to revolutionize the 3D printing industry.

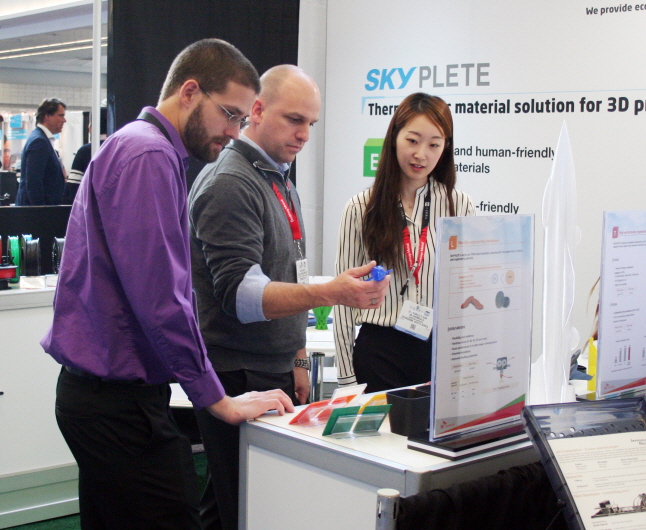

[Photo]

SK chemicals staff talking to customers about its SKYPLETE at the 2017 RAPID TCT held in Pittsburgh.

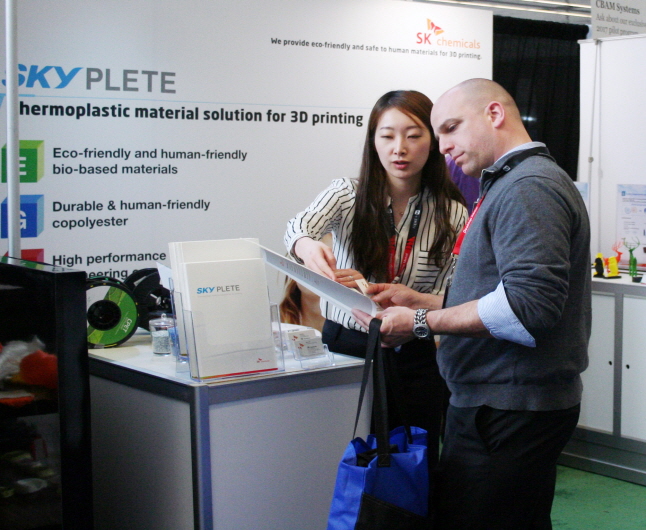

[Photo]

SKYPLETE is ideal for making industrial prototypes, artworks, and educational materials because of its glossy surface.

[Glossary]

* Volatile organic compounds (VOCs):

Volatile organic compounds are organic compounds that easily become vapors or gases under certain temperature or pressure conditions, which are causes of photochemical smog.

* Bisphenol A:

Bisphenol A, a chemical ingredient for epoxy resin and polycarbonate, is classified as an endocrine disruptor that causes a reduction in sperm count and feminizing effects in males, and has been banned for use with baby milk bottles since 2012.

* 3D printer filament:

3D printer filament is an ink-like basic ingredient for 3D printing and materials such as acrylonitrile butadiene styrene (ABS) and polylactic acid (PLA), which are used for thermoplastic materials

* TPU(Thermoplastic Poly Urethane):

Thermoplastic polyurethane elastomer is a soft, elastic material used for synthetic leather, shoe soles, and the inner lining of outdoor clothing items.

* PLA(Poly Lactic Acid):

As polylactic acid is made of biodegradable, environmentally friendly corn and sugar cane, there is no odor like acrylonitrile butadiene styrene and it causes no harm to the human body. Although it is good for 3D printing when used for filaments in a low-temperature environment due to its shrink-resistant properties, it is not suitable for high-temperature conditions that exceed 55°C