- SK chemicals will showcase the world's first commercialized chemically recycled materials and biomaterials at “K 2022” held in Germany

- The company will contribute to the global eco-friendly plastic market, following the trend of recycled materials becoming obligatory in the EU and US

As the company leading the global eco-transition, SK chemicals will display various eco-friendly plastic materials at the world’s largest trade fair for plastic and rubber.

SK chemicals (CEO: Jeon Kwang-hyun) announced on the 18th that the company will participate in “K 2022”, a plastic and rubber industry trade fair held in Dusseldorf, Germany from the 19th to the 26th. “K 2022” is the world's largest plastic and rubber industry trade fair held every three years. Specifically in this year, key issues in the industry such as ▲circular economy, ▲digitalization, and ▲climate protection will be discussed.

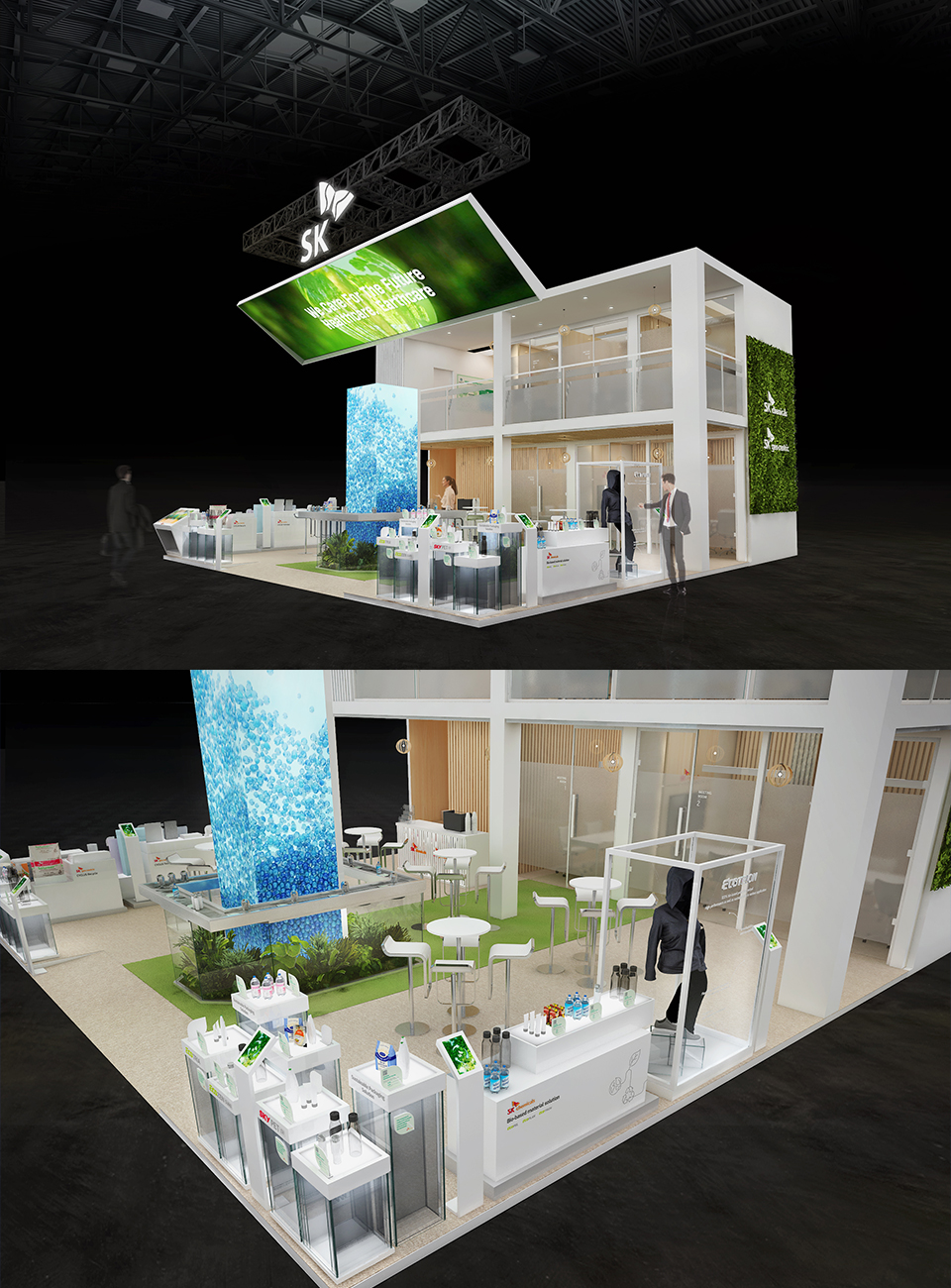

SK chemicals prepared an exhibition space where visitors can experience the “plastic circular economy” along with “green materials” that can respond to the global trend. SK chemicals’ booth features an eco-friendly design with the exhibition space created using chemically-recycled copolyester materials to emphasize the concepts of “sustainability” and “circular economy” of the chemical business.

In particular, SK chemicals will focus on recycled plastics and bio-based plastics in this year’s trade fair. A great deal of effort went into the technology and development of these two “green materials” to meet the needs of the eco-friendly market. SK chemicals will also showcase ECOPEL, a high-functional elastic material aimed at the electric, electronic, automobile, film, and fiber markets, for the first time.

SK chemicals’ lineup of “Sustainable Packaging Solutions (SPS)” consists of ▲“ECOTRIA CR-Series”, produced using chemically-recycled raw materials, ▲“ECOTRIA R-Series”, produced using post-consumer recycled (PCR), and ▲“Claro”, which consumers can recycle into PET after use. After introducing “ECOTRIA R”, a material produced with physical recycling technology, at “K 2019” three years ago, the company has expanded its chemical recycling portfolio through rapid technology development and commercialization for the first time in the world. “ECOZEN Pro”, which will be displayed together with SPS, is a material with improved impact resistance, durability and is dishwasher safe so it’s perfect for sports bottles, blenders, and airtight containers.

In addition, “SKYPET CR”, a PET produced with chemical recycling technology, will be displayed along with Samdasoo RE:Born bottled water, fibers, and films that are produced with this material. With the EU, US, and other regions applying stricter regulations such as a mandatory target of 30% or higher recycled plastic use by 2030, much interest is expected from food container, label, and industrial continuous glass fiber industries.

Expanding options for sustainable materials through the introduction of new biomaterials As a bio-based plastic material, SK chemicals will exhibit ECOTRION, a bio-polyol made entirely of plant-based materials. The company will also unveil ECOPLAN, a highly flexible biodegradable material, and ECOPEL, a thermoplastic elastic material, both of which were developed using ECOTRION.

ECOTRION is a new material aiming to replace polyol, which uses existing petroleum-based raw materials, with bio-materials. ECOTRION is used as a key material for synthetic leather, clothing, coating and adhesive materials, and bio-spandex.

ECOPLAN, a highly flexible and biodegradable material that can be used for film packagings such as standard plastic garbage bags, shopping bags, and zipper bags, has superior flexibility and processability compared to existing PLA and PLA/PBAT materials, as well as high bio-content and transparency.

ECOPEL, a bio-thermoplastic elastic material, is expected to become a sustainable solution in the elastomer market as it can increase the bio-content up to 64% while retaining the same mechanical properties equivalent to those of existing petrochemical materials.

Recently, in Europe, where the use of recycled plastics will soon be compulsory, a new plastic tax of 0.8 euros per kg of discarded plastic is being considered, and the United States is also in the process of enforcing legislation on the use of recycled plastics. According to a report by Wood McKinsey in 2021, the global PET market is about 90 million tons per year, and recycled PET is about 11% or 9.7 million tons. Most of it is “Mechanical Recycling PET (MR-PET),” and the chemical recycled PET (CR-PET) market is just beginning.

Kim Hyun-seok, head of SK chemicals' GC Business Division, said, “The global chemical industry is changing into a competition for eco-friendly and recycling technologies based on the paradigm of “sustainability” and “circular economy,” and added, “We plan to actively introduce SK chemicals’ portfolio of “green materials” and eco-friendly technologies to the global market, which will provide solutions to global warming problems through greenhouse gas reduction.”

1. Copolyester: Highly transparent thermoplastic amorphous resin with excellent chemical resistance. It can be safely used without fear of detecting bisphenol A, a type of environmental hormone.

2. Chemical Recycling: Technology for recovering raw materials that can make clean plastics through the chemical reaction of collected waste plastics.

3. PLA (Polylactic Acid): A typical biodegradable resin made from starch extracted from corn. PLA is stiff and therefore breaks and tears easily. To compensate for these disadvantages, a biodegradable material produced by adding highly flexible PBAT to PLA is used.

# Photo description: Aerial view of the booth of SK chemicals for K2022 in Germany and product display